Sliding Systems has entered into a new distribution agreement with Regout Balance...

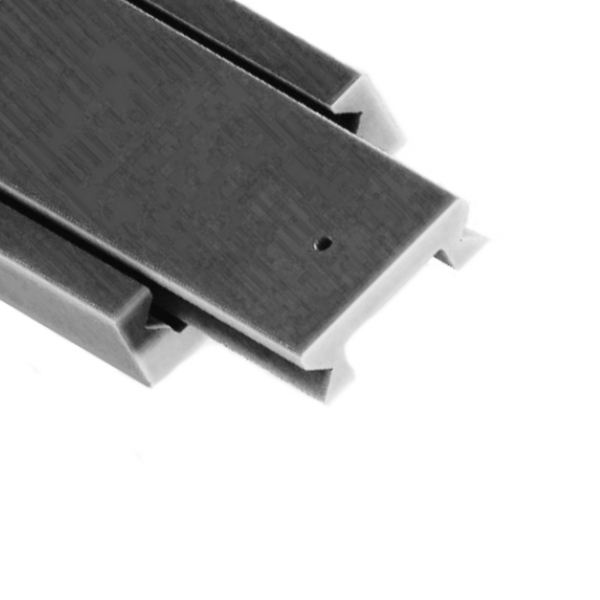

Aluminium Radial Slides

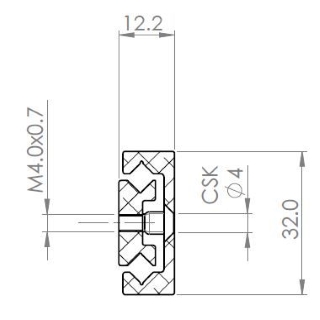

Profile Width: 12mm

Height: 32mm

Profile Width: 12mm

Height: 32mm

Closed Length:

300mm - 800mm

Extended Length:

162mm - 582mm

Max load capacity:

20 - 56kg per pair

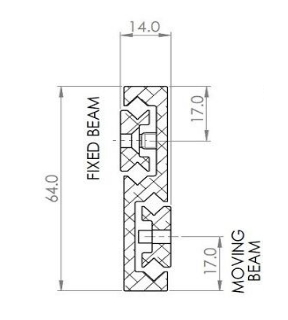

Profile Width: 14mm

Height: 64mm

Profile Width: 14mm

Height: 64mm

Closed Length:

300mm - 800mm

Extended Length:

325mm - 1165mm

Max load capacity:

10 - 30kg per pair

Profile Width: 17mm

Height: 52mm

Profile Width: 17mm

Height: 52mm

Closed Length:

300mm - 1000mm

Extended Length:

138mm - 628mm

Max load capacity:

60 - 114kg per pair

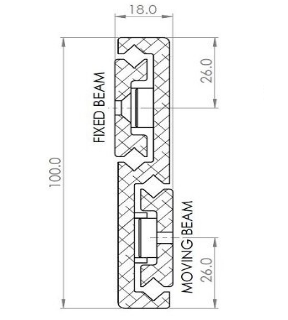

Profile Width: 18mm

Height: 100mm

Profile Width: 18mm

Height: 100mm

Closed Length:

300mm - 1000mm

Extended Length:

305mm - 1145mm

Max load capacity:

20 - 78kg per pair

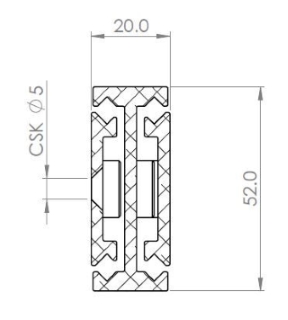

Profile Width: 20mm

Height: 52mm

Profile Width: 20mm

Height: 52mm

Closed Length:

300mm - 1000mm

Extended Length:

300mm - 1000mm

Max load capacity:

125 - 170kg per pair

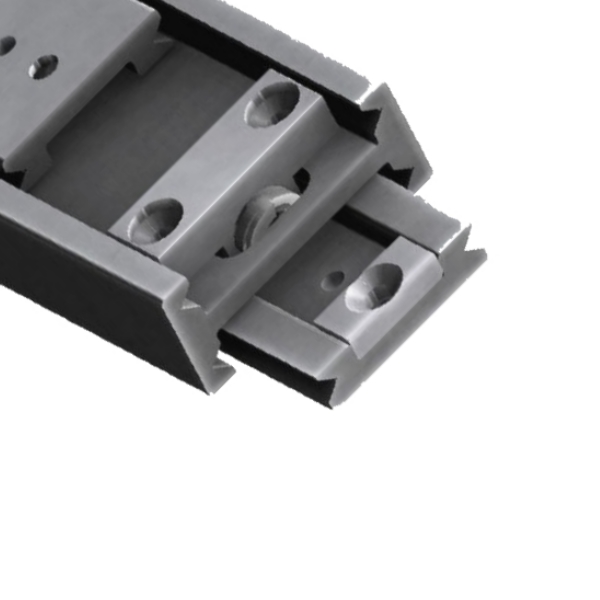

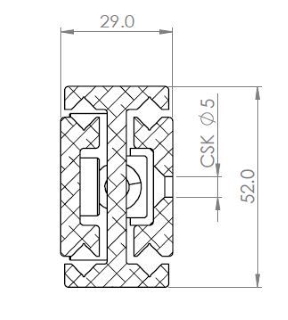

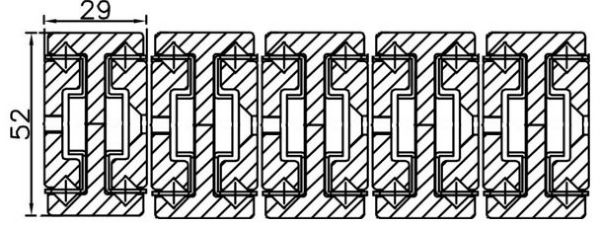

Profile Width: 29mm

Height: 52mm

Profile Width: 29mm

Height: 52mm

Closed Length:

300mm - 1000mm

Extended Length:

275mm - 1115mm

Max load capacity:

135 - 220kg per pair

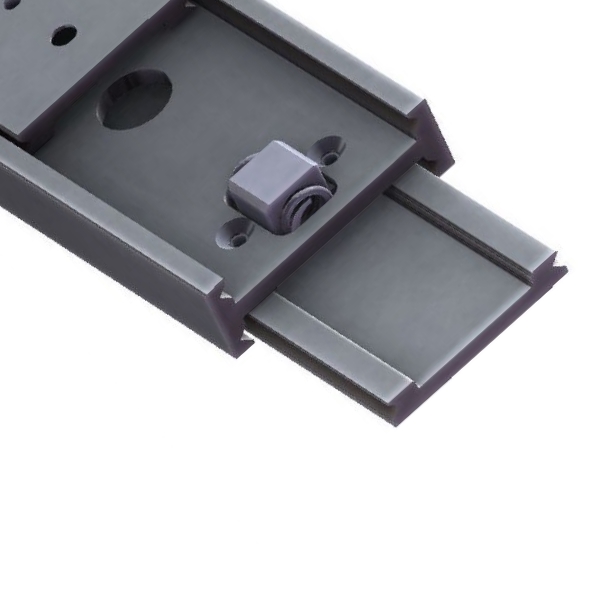

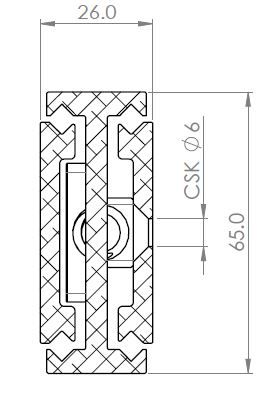

Profile Width: 26mm

Height: 65mm

Profile Width: 26mm

Height: 65mm

Closed Length:

300mm - 1600mm

Extended Length:

295mm - 1595mm

Max load capacity:

181 - 392kg per pair

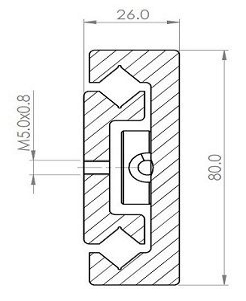

Profile Width: 26mm

Height: 80mm

Profile Width: 26mm

Height: 80mm

Closed Length:

300mm - 1000mm

Extended Length:

100mm - 620mm

Max load capacity:

220 - 300kg per pair

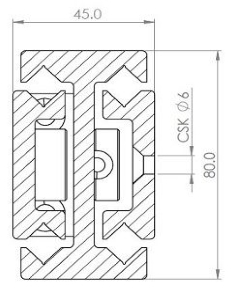

Profile Width: 45mm

Height: 80mm

Profile Width: 45mm

Height: 80mm

Closed Length:

300mm - 1000mm

Extended Length:

170mm - 1100mm

Max load capacity:

300 - 400kg per pair

Profile Width: 156mm

Height: 52mm

Profile Width: 156mm

Height: 52mm

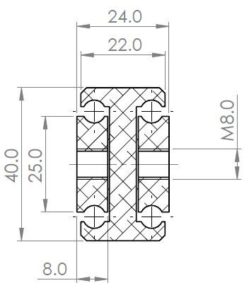

4015.ADTS040 – ADTS-40

4015.ADTS040 – ADTS-40