Sliding Systems has entered into a new distribution agreement with Regout Balance...

Professional Range – Aluminium Non-Corrosive 6082

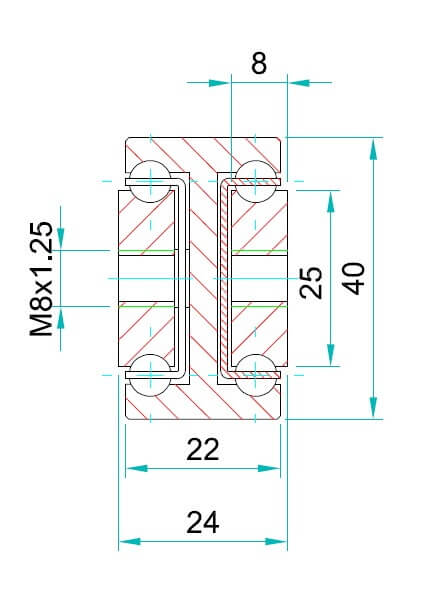

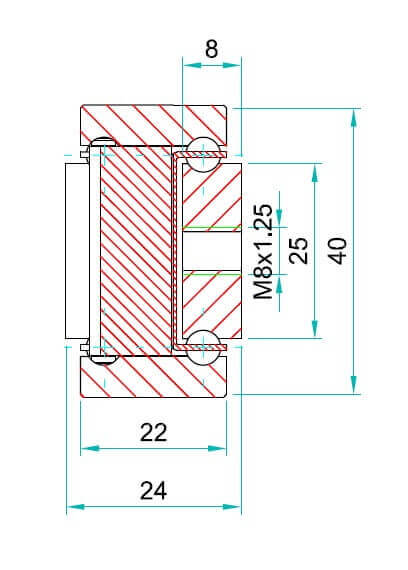

Profile Width: 24mm

Height: 40mm

Profile Width: 24mm

Height: 40mm

Closed Length:

150mm - 1500mm

Extended Length:

150mm - 1500mm

Max load capacity:

35 - 125kg per pair

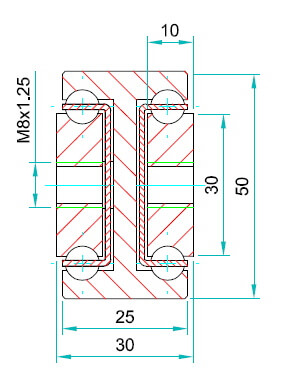

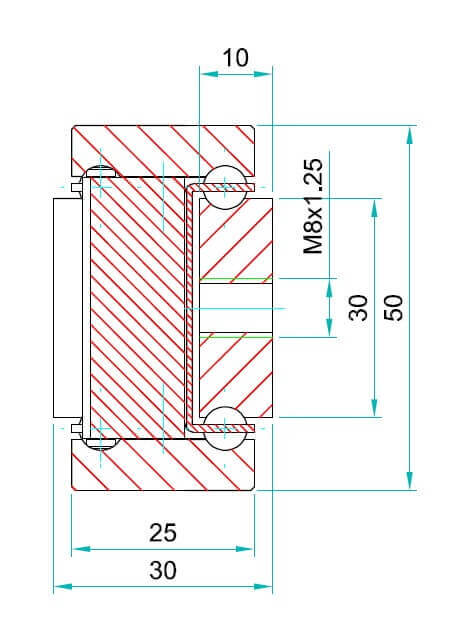

Profile Width: 30mm

Height: 50mm

Profile Width: 30mm

Height: 50mm

Closed Length:

150mm - 1500mm

Extended Length:

150mm - 1500mm

Max load capacity:

66 - 180kg per pair

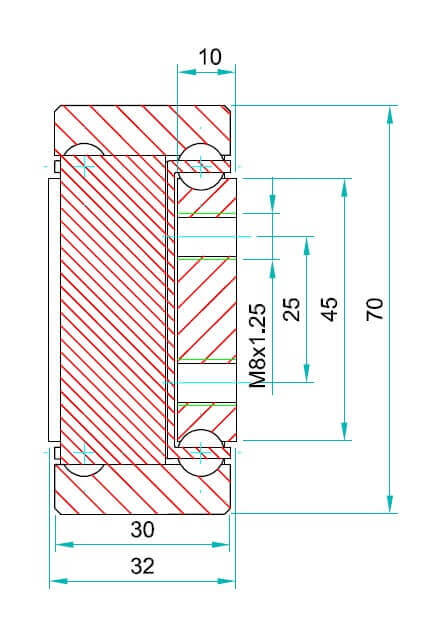

Profile Width: 32mm

Height: 70mm

Profile Width: 32mm

Height: 70mm

Closed Length:

200mm - 2000mm

Extended Length:

200mm - 2000mm

Max load capacity:

105 - 330kg per pair

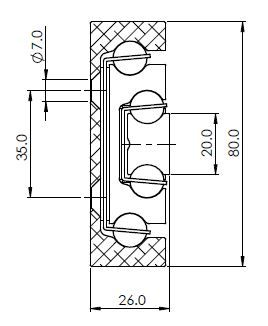

Profile Width: 26mm

Height: 80mm

Profile Width: 26mm

Height: 80mm

Closed Length:

300mm - 1500mm

Extended Length:

285mm - 1485mm

Max load capacity:

150 - 330kg per pair

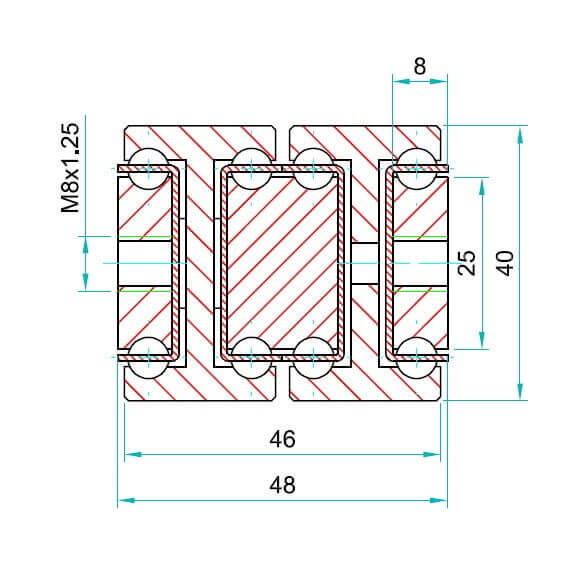

Profile Width: 48mm

Height: 40mm

Profile Width: 48mm

Height: 40mm

Closed Length:

200mm - 1200mm

Extended Length:

400mm - 2400mm

Max load capacity:

28 - 50kg per pair

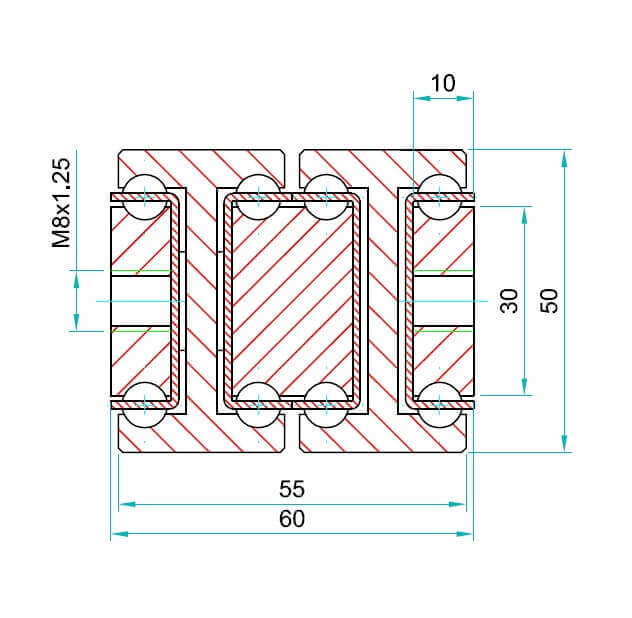

Profile Width: 60mm

Height: 50mm

Profile Width: 60mm

Height: 50mm

Closed Length:

200mm - 1200mm

Extended Length:

400mm - 2400mm

Max load capacity:

34 - 80kg per pair

Profile Width: 64mm

Height: 70mm

Profile Width: 64mm

Height: 70mm

Closed Length:

200mm - 1200mm

Extended Length:

400mm - 2400mm

Max load capacity:

48 - 99kg per pair

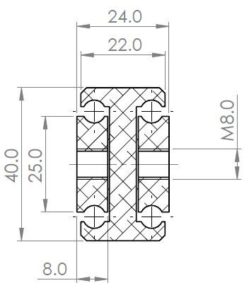

Profile Width: 24mm

Height: 40mm

Profile Width: 24mm

Height: 40mm

Closed Length:

200mm - 1500mm

Extended Length:

200mm - 1500mm

Max load capacity:

35 - 125kg per pair

Profile Width: 30mm

Height: 50mm

Profile Width: 30mm

Height: 50mm

Closed Length:

200mm - 1500mm

Extended Length:

200mm - 1500mm

Max load capacity:

66 - 180kg per pair

Profile Width: 32mm

Height: 70mm

Profile Width: 32mm

Height: 70mm

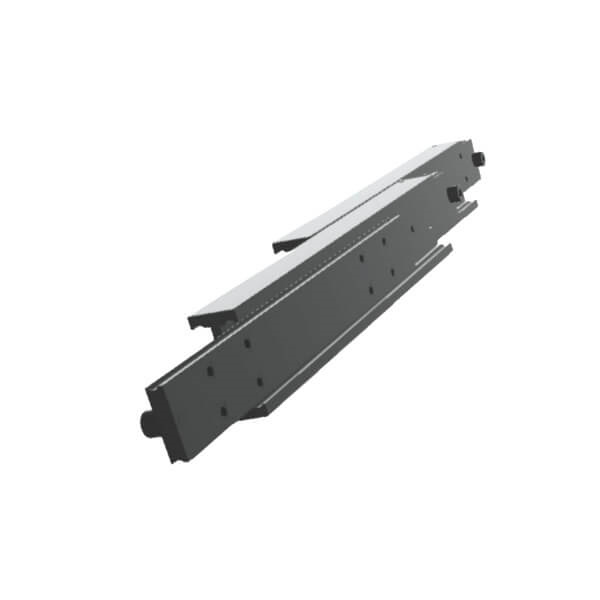

4015.ADTS040 – ADTS-40

4015.ADTS040 – ADTS-40