Sliding Systems has entered into a new distribution agreement with Regout Balance...

4013.8045 (300-400kg)

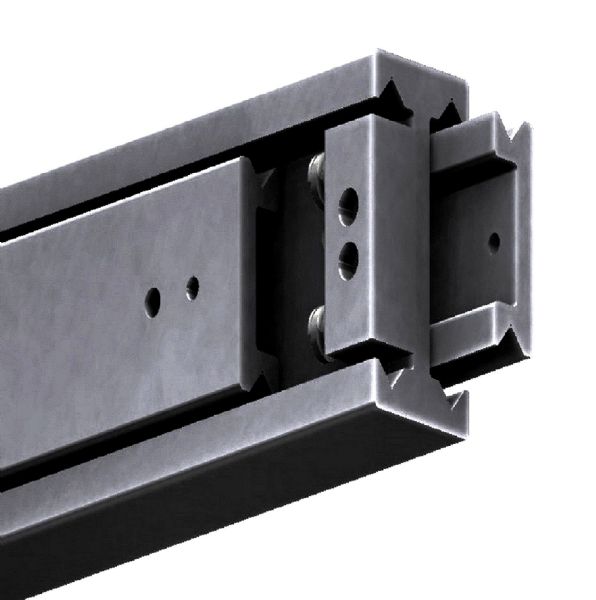

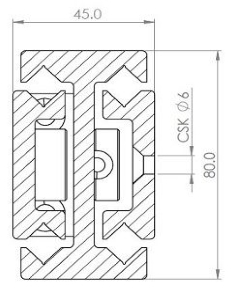

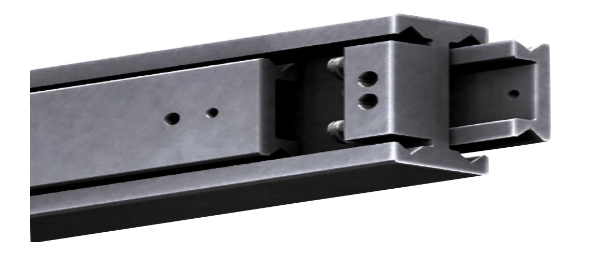

The 8045 Radial Slide is an extreme duty aluminium telescopic slide (300-400Kg/pair) suitable for a wide range of applications. At 650mm 1 pair has a load capacity of 390Kg with a standard extension of 750mm. The cross roller bearing system is ideal for use on military and emergency vehicle drawers where lightweight, corrosion resistant material is demanded. The 8045 has also been designed into military RADAR systems and modified shipping containers to totally withdraw the bar area.

Aluminium Radial Slides utilise a unique crossed roller bearing system which makes full length contact within the ball race and eradicates bearing indentation (brinelling) and migration. This is a very rugged slide and, due to the unique roller design, outperforms similar ball bearing based products. The rear stop is fitted with die spring absorbers to cushion and protect when subject to shock loading.

Cross roller bearings are best suited to applications like aircraft seating where offset loads and point contact stresses cause significant indentation in the ball race and subsequent slide failure. However, due to the rigidity of the slides, there is no play in the beams and this allows for deflection free extension.

The larger profiles can take considerable loading and with the option of up to 130% extension, are rigid enough support emergency truck drawers & pump carriers to 4000N. The benefit also being that the slides offer a considerable weight saving to steel and are non-corrosive. Thus, negating the need to specify expensive, full stainless steel sections. These complement our non-corrosive handles, locks and tilting drawers.

The 8045 Radial Slide is manufactured from 6005a aluminium with the bearing races milled for tolerance. The finish is self-colour anodization, however there are various options. The bearings are hardened steel and chromed rods.

This slide is manufactured to order, please allow 4-5 weeks or consult our sales engineers to confirm best availability.

Code | Closed Length (mm) | Extension (mm) | Max Load Capacity (kg) |

|---|---|---|---|

| 4013.8045.0300 | 300mm | 170mm | 350kg |

| 4013.8045.0350 | 350mm | 270mm | 355kg |

| 4013.8045.0400 | 400mm | 370mm | 360kg |

| 4013.8045.0450 | 450mm | 470mm | 370kg |

| 4013.8045.0500 | 500mm | 570mm | 380kg |

| 4013.8045.0550 | 550mm | 550mm | 390kg |

| 4013.8045.0600 | 600mm | 650mm | 400kg |

| 4013.8045.0650 | 650mm | 750mm | 390kg |

| 4013.8045.0700 | 700mm | 700mm | 380kg |

| 4013.8045.0750 | 750mm | 750mm | 370kg |

| 4013.8045.0800 | 800mm | 800mm | 355kg |

| 4013.8045.0850 | 850mm | 800mm | 340kg |

| 4013.8045.0900 | 900mm | 900mm | 325kg |

| 4013.8045.0950 | 950mm | 1000mm | 315kg |

| 4013.8045.1000 | 1000mm | 1100mm | 300kg |

Data Sheet & main product information -

4013.8045 - 300mm - 3D STEP File

4013.8045 length 300mm

4013.8045 - 350mm - 3D STEP File

4013.8045 length 350mm

4013.8045 - 400mm - 3D STEP File

4013.8045 length 400mm

4013.8045 - 450mm - 3D STEP File

4013.8045 length 450mm

4013.8045 - 500mm - 3D STEP File

4013.8045 length 500mm

4013.8045 - 550mm - 3D STEP File

4013.8045 length 550mm

4013.8045 - 600mm - 3D STEP File

4013.8045 length 600mm

4013.8045 - 650mm - 3D STEP File

4013.8045 length 650mm

4013.8045 - 700mm - 3D STEP File

4013.8045 length 700mm

4013.8045 - 750mm - 3D STEP File

4013.8045 length 750mm

4013.8045 - 800mm - 3D STEP File

4013.8045 length 800mm

4013.8045 - 850mm - 3D STEP File

4013.8045 length 850mm

4013.8045 - 900mm - 3D STEP File

4013.8045 length 900mm

4013.8045 - 950mm - 3D STEP File

4013.8045 length 950mm

4013.8045 - 1000mm - 3D STEP File

4013.8045 length 1000mm

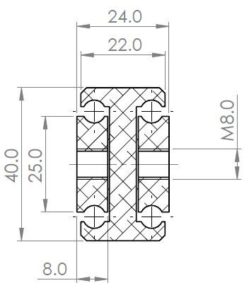

4015.ADTS040 – ADTS-40

4015.ADTS040 – ADTS-40