Sliding Systems has entered into a new distribution agreement with Regout Balance...

Bottom Mount C-938 Generator Slide

The C-938 & 938L Bottom Mount Slides are designed for floor mounted applications such as pump and generator carriers on special vehicles. They are ideally suited in applications where standard ball bearings would be subject to dirt ingress. The sealed bearings and open channel are ideally suited in rough terrain use. The locking and non-locking versions can be purchased separately and fitted as a pair with any number being used to spread the load. The front accessed locking tab provides the lock closed and fully extended function. These slides are particularly suited to uneven floor surfaces often found in fire trucks.

1. Standard C-938 has no locking features.

2. Optional lock-in/lock-out feature is available.

3. Finish: E-Coat conversion coating or clear zinc commercial plating.

4. Load capacity is based on one slide at full extension with the load (centre of gravity) at the midpoint of the slide (chassis section). For increased load capacity, multiply the nnumber of slides required for the application.

5. Stated load capacity has a 100% static (non-moving) load safety factor at full extension. Slide is not intended to be operated with continuous loading which exceeds stated capacities.

6. Ball bearing rollers are lubricated with -45°F to +350°F temperature range grease.

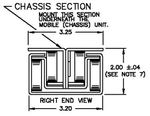

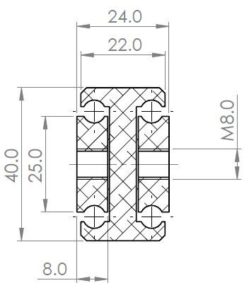

7. Measured in the closed (retracted position).

8. Slide members and plate are made of 12 guage (.105) cold rolled steel.

9. Other non-standard options including finishes and stainless steel slides are available. These options require a special reference number.

10. No mounting hardware supplied.

11. Slide is designed for compression or suspension loading.

Dimensions are in imperial ", Loading in metric Kg

All General Devices slides are manufactured to order, so please allow 5-6 weeks, unless subscribed to our stockholding programme. 3D .stp files available on request.

Code | Closed Length (in) | Extension (in) | Max Load Capacity (kg) |

|---|---|---|---|

| 4012.C938.012 | 12in | 12in | 180kg |

| 4012.C938.014 | 14in | 14in | 151kg |

| 4012.C938.016 | 16in | 16in | 128kg |

| 4012.C938.018 | 18in | 18in | 112kg |

| 4012.C938.020 | 20in | 20in | 99kg |

| 4012.C938.022 | 22in | 22in | 90kg |

| 4012.C938.024 | 24in | 24in | 81kg |

| 4012.C938.026 | 26in | 26in | 74kg |

| 4012.C938.028 | 28in | 28in | 70kg |

| 4012.C938.030 | 30in | 30in | 63kg |

| 4012.C938.032 | 32in | 32in | 59kg |

| 4012.C938.034 | 34in | 34in | 56kg |

| 4012.C938.036 | 36in | 36in | 54kg |

| 4012.C938.038 | 38in | 38in | 49kg |

| 4012.C938.040 | 40in | 40in | 47kg |

| 4012.C938.042 | 42in | 42in | 45kg |

| 4012.C938.044 | 44in | 44in | 42kg |

| 4012.C938.046 | 46in | 46in | 40kg |

| 4012.C938.048 | 48in | 48in | 38kg |

Data Sheet & main product information -

Installation Sheet -

4012.C938 - 304mm (12") - 3D STEP FILE -

4012.C938 length 304mm (12")

4012.C938 - 356mm (14") - 3D STEP FILE -

4012.C938 length 356mm (14")

4012.C938 - 406mm (16") - 3D STEP FILE -

4012.C938 length 406mm (16")

4012.C938 - 457mm (18") - 3D STEP FILE -

4012.C938 length 457mm (18")

4012.C938 - 508mm (20") - 3D STEP FILE -

4012.C938 length 508mm (20")

4012.C938 - 559mm (22") - 3D STEP FILE -

4012.C938 length 559mm (22")

4012.C938 - 610mm (24") - 3D STEP FILE -

4012.C938 length 610mm (24")

4012.C938 - 660mm (26") - 3D STEP FILE -

4012.C938 length 660mm (26")

4012.C938 - 711mm (28") - 3D STEP FILE -

4012.C938 length 711mm (28")

4012.C938 - 762mm (30") - 3D STEP FILE -

4012.C938 length 762mm (30")

4012.C938 - 812mm (32") - 3D STEP FILE -

4012.C938 length 812mm (32")

4012.C938 - 864mm (34") - 3D STEP FILE -

4012.C938 length 864mm (34")

4012.C938 - 914mm (36") - 3D STEP FILE -

4012.C938 length 914mm (36")

4012.C938 - 965mm (38") - 3D STEP FILE -

4012.C938 length 965mm (38")

4012.C938 - 1016mm (40") - 3D STEP FILE -

4012.C938 length 1016mm (40")

4012.C938 - 1067mm (42") - 3D STEP FILE -

4012.C938 length 1067mm (42")

4012.C938 - 1117mm (44") - 3D STEP FILE -

4012.C938 length 1117mm (44")

4012.C938 - 1168mm (46") - 3D STEP FILE -

4012.C938 length 1168mm (46")

4012.C938 - 1219mm (48") - 3D STEP FILE -

4012.C938 length 1219mm (48")

4015.ADTS040 – ADTS-40

4015.ADTS040 – ADTS-40