Sliding Systems has entered into a new distribution agreement with Regout Balance...

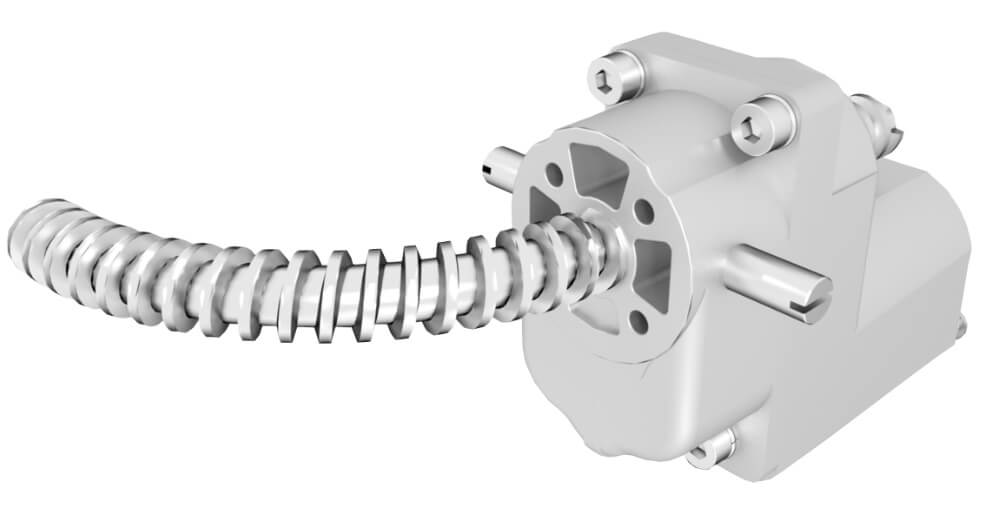

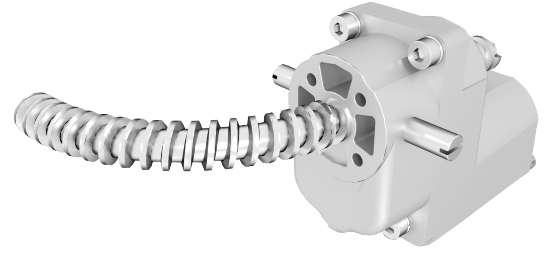

ACTUATORS/FLEX SCREW

The flexible screw actuator, LAF series, a product derived from the LAT version, is indicated where the fixing point of the part to be moved is difficult to reach or where there are problems of space, allowing the recovery of the screw space and adapting it to the existing space.

It allows the handling of loads even up to 350 N and also this version can be equipped with a hall effect encoder to control the positions and the direction of advance through the appropriate electronics.

Data Sheet -

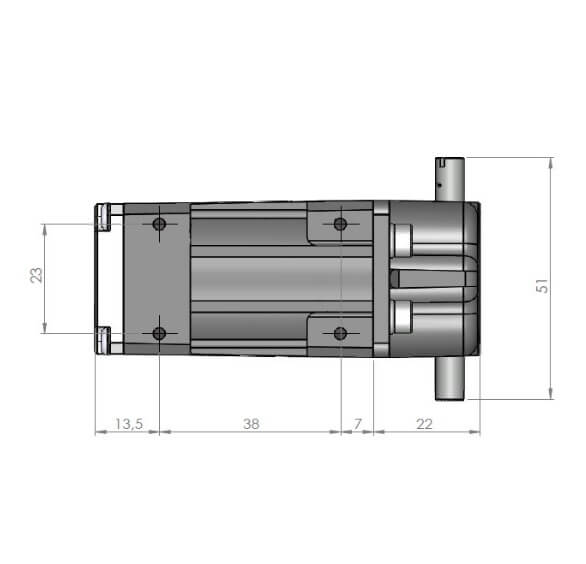

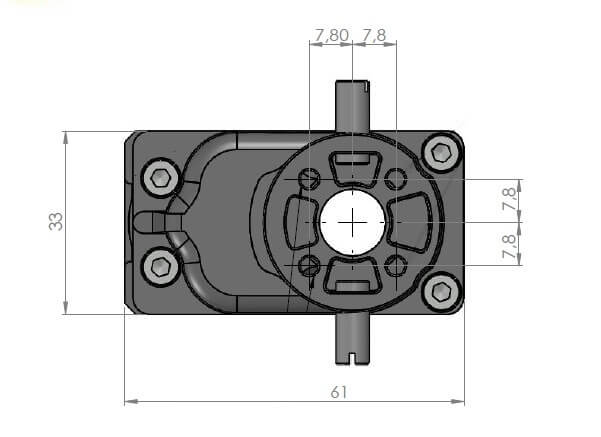

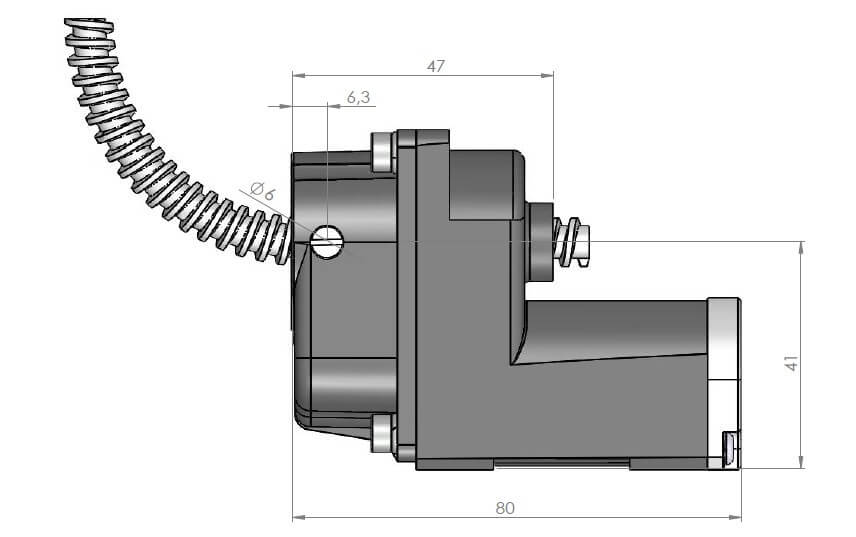

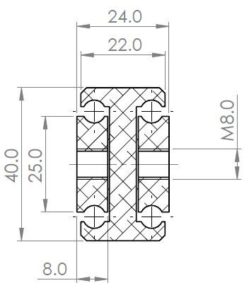

Actuators With Flex Screw Dimensions -

Encoder Datasheet -

Actuators/Flex Screw Enquiry

4015.ADTS040 – ADTS-40

4015.ADTS040 – ADTS-40