Sliding Systems has entered into a new distribution agreement with Regout Balance...

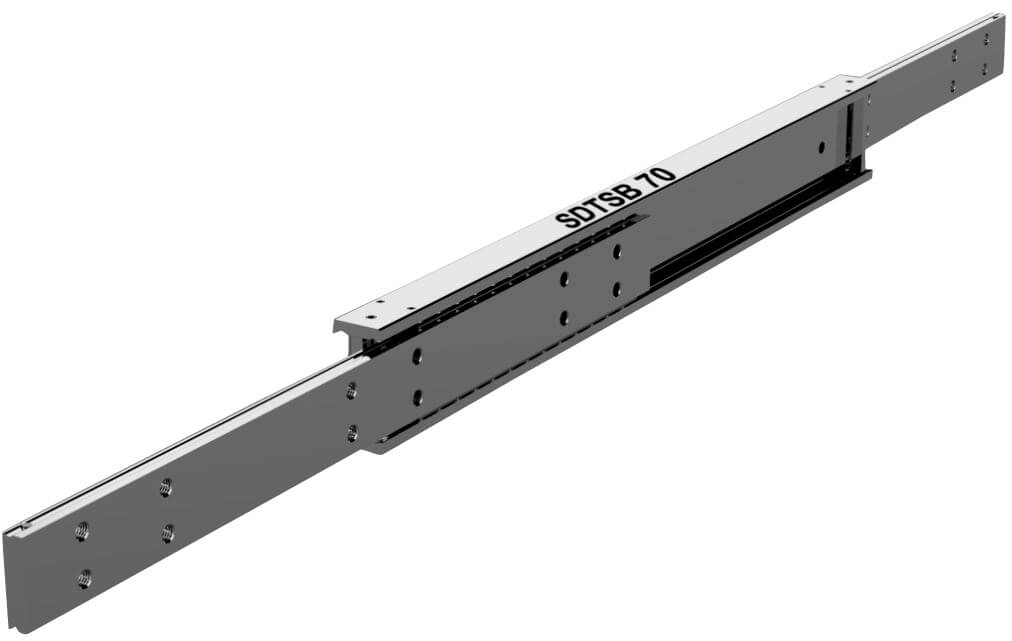

4015.SDTSB70 (154-540kg)

The SDTSB-70 offers total extension front and rear. This is made possible by an internal rocker device which releases each beam in sequence. Ideal for thru-truck drawers or train battery boxes where access from either side may be limited. This is a heavy load/duty full extension telescopic slide (154-540 kg/pair) suitable for a wide range of applications. At 550mm 1 pair has a full extension load capacity of 490 kg.

Constructed from milled stainless steel (inox) 316L sections, with machined ball tracks for accuracy, it has excellent levels of shock and vibration resistance. Accordingly, the product is well suited to operating in extreme high temperatures through to as low as cryogenic. The slide beams, cages and ball bearings are manufactured from austenitic grade 316L (1.4404). End stop bolts and retaining pins are austenitic grade 304 (1.4301), completing the corrosion protection, There is the bespoke option to manufacture an all 316L product on higher production volumes.

The beam release mechanism guarantees that one beam is held firm whilst the other travels. Unlike some systems where the load is pulled through the slide and the ball cages misalign and jam.

Due to the extreme strength of the mobile 'I' beam, this slide is robust to applied loads when in the extended position making it an excellent choice for dynamic applications. Unlike many other slides manufactured from rolled steel 'C' sections. There are no plastic parts in the manufacture of this range, making it ideal for high temperature use. Grade 316L is an austenitic stainless steel with a very low electro-magnetic signature, so ideal for defence applications.

SDTSB slides on accurate robotic pick & place or high speed shuttles require factory adaptation and customer in situ testing, prior to committing to production. The beams are precision ground for accuracy and ball cages laser cut. However, constant low force usage will lead to some bearing migration without an operator to realign about every 2,000 cycles. The slides are limited to operational speeds of <0.3m/s. We are starting a laser hardening programme for the ball races, to launch in Jan 2024. This will increase the hardness to 62hrc, operational speeds to 0.7m/s and reduce the operational forces to traverse. This will make the slide ideal for robotic usage with a substantial economy over expensive induction hardened beams.

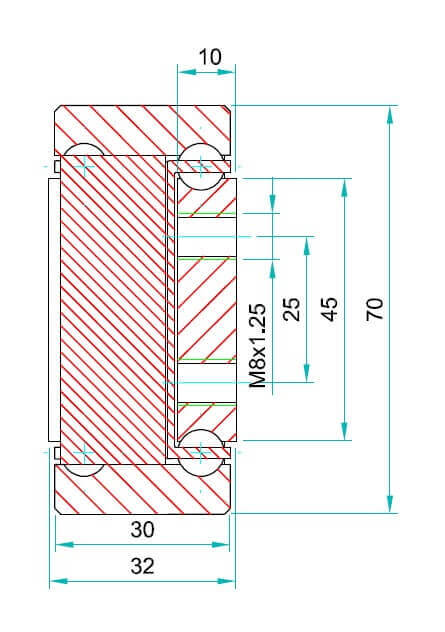

The SDTSB-70 drawer slide may also be fitted in the minor axis (flat). However, the load capacity will be reduced by 60-80% of the stated loading. A single SDTSB-70 weighs 13.42 kg per metre.

The SDTSB-70 can be purchased online for global delivery by following this link. Please allow 5-6 weeks for manufacture, unless subscribed to our stock holding programme which facilitates next day supply.

Code | Closed Length (mm) | Extension (mm) | Max Load Capacity (kg) |

|---|---|---|---|

| 4015.SDTSB070.0200 | 200mm | 200mm | 420kg |

| 4015.SDTSB070.0250 | 250mm | 250mm | 430kg |

| 4015.SDTSB070.0300 | 300mm | 300mm | 440kg |

| 4015.SDTSB070.0350 | 350mm | 350mm | 450kg |

| 4015.SDTSB070.0400 | 400mm | 400mm | 460kg |

| 4015.SDTSB070.0450 | 450mm | 450mm | 470kg |

| 4015.SDTSB070.0500 | 500mm | 500mm | 480kg |

| 4015.SDTSB070.0550 | 550mm | 550mm | 490kg |

| 4015.SDTSB070.0600 | 600mm | 600mm | 500kg |

| 4015.SDTSB070.0650 | 650mm | 650mm | 510kg |

| 4015.SDTSB070.0700 | 700mm | 700mm | 520kg |

| 4015.SDTSB070.0750 | 750mm | 750mm | 530kg |

| 4015.SDTSB070.0800 | 800mm | 800mm | 540kg |

| 4015.SDTSB070.0850 | 850mm | 850mm | 526kg |

| 4015.SDTSB070.0900 | 900mm | 900mm | 512kg |

| 4015.SDTSB070.0950 | 950mm | 950mm | 490kg |

| 4015.SDTSB070.1000 | 1000mm | 1000mm | 476kg |

| 4015.SDTSB070.1050 | 1050mm | 1050mm | 462kg |

| 4015.SDTSB070.1100 | 1100mm | 1100mm | 455kg |

| 4015.SDTSB070.1150 | 1150mm | 1150mm | 441kg |

| 4015.SDTSB070.1200 | 1200mm | 1200mm | 427kg |

| 4015.SDTSB070.1250 | 1250mm | 1250mm | 420kg |

| 4015.SDTSB070.1300 | 1300mm | 1300mm | 406kg |

| 4015.SDTSB070.1350 | 1350mm | 1350mm | 385kg |

| 4015.SDTSB070.1400 | 1400mm | 1400mm | 364kg |

| 4015.SDTSB070.1450 | 1450mm | 1450mm | 343kg |

| 4015.SDTSB070.1500 | 1500mm | 1500mm | 322kg |

| 4015.SDTSB070.1550 | 1550mm | 1550mm | 294kg |

| 4015.SDTSB070.1600 | 1600mm | 1600mm | 266kg |

| 4015.SDTSB070.1650 | 1650mm | 1650mm | 245kg |

| 4015.SDTSB070.1700 | 1700mm | 1700mm | 238kg |

| 4015.SDTSB070.1750 | 1750mm | 1750mm | 220kg |

| 4015.SDTSB070.1800 | 1800mm | 1800mm | 210kg |

| 4015.SDTSB070.1850 | 1850mm | 1850mm | 196kg |

| 4015.SDTSB070.1900 | 1900mm | 1900mm | 178kg |

| 4015.SDTSB070.1950 | 1950mm | 1950mm | 168kg |

| 4015.SDTSB070.2000 | 2000mm | 2000mm | 154kg |

Data Sheet & main product information -

Technical Description & Maintenance -

SDTSB70 length 200mm- 3D STEP FILE -

4015.SDTSB70 length 200mm

SDTSB70 length 250mm- 3D STEP FILE -

4015.SDTSB70 length 250mm

SDTSB70 length 300mm- 3D STEP FILE -

4015.SDTSB70 length 300mm

SDTSB70 length 350mm- 3D STEP FILE -

4015.SDTSB70 length 350mm

SDTSB70 length 400mm- 3D STEP FILE -

4015.SDTSB70 length 400mm

SDTSB70 length 450mm- 3D STEP FILE -

4015.SDTSB70 length 450mm

SDTSB70 length 500mm- 3D STEP FILE -

4015.SDTSB70 length 500mm

SDTSB70 length 550mm- 3D STEP FILE -

4015.SDTSB70 length 550mm

SDTSB70 length 600mm- 3D STEP FILE -

4015.SDTSB70 length 600mm

SDTSB70 length 650mm- 3D STEP FILE -

4015.SDTSB70 length 650mm

SDTSB70 length 700mm- 3D STEP FILE -

4015.SDTSB70 length 700mm

SDTSB70 length 750mm- 3D STEP FILE -

4015.SDTSB70 length 750mm

SDTSB70 length 800mm- 3D STEP FILE -

4015.SDTSB70 length 800mm

SDTSB70 length 850mm- 3D STEP FILE -

4015.SDTSB70 length 850mm

SDTSB70 length 900mm- 3D STEP FILE -

4015.SDTSB70 length 900mm

SDTSB70 length 950mm- 3D STEP FILE -

4015.SDTSB70 length 950mm

SDTSB70 length 1000mm- 3D STEP FILE -

4015.SDTSB70 length 1000mm

SDTSB70 length 1050mm- 3D STEP FILE -

4015.SDTSB70 length 1050mm

SDTSB70 length 1100mm- 3D STEP FILE -

4015.SDTSB70 length 1100mm

SDTSB70 length 1150mm- 3D STEP FILE -

4015.SDTSB70 length 1150mm

SDTSB70 length 1200mm- 3D STEP FILE -

4015.SDTSB70 length 1200mm

SDTSB70 length 1250mm- 3D STEP FILE -

4015.SDTSB70 length 1250mm

SDTSB70 length 1300mm- 3D STEP FILE -

4015.SDTSB70 length 1300mm

SDTSB70 length 1350mm- 3D STEP FILE -

4015.SDTSB70 length 1350mm

SDTSB70 length 1400mm- 3D STEP FILE -

4015.SDTSB70 length 1400mm

SDTSB70 length 1450mm- 3D STEP FILE -

4015.SDTSB70 length 1450mm

SDTSB70 length 1500mm- 3D STEP FILE -

4015.SDTSB70 length 1500mm

SDTSB70 length 1550mm- 3D STEP FILE -

4015.SDTSB70 length 1550mm

SDTSB70 length 1600mm- 3D STEP FILE -

4015.SDTSB70 length 1600mm

SDTSB70 length 1650mm- 3D STEP FILE -

4015.SDTSB70 length 1650mm

SDTSB70 length 1700mm- 3D STEP FILE -

4015.SDTSB70 length 1700mm

SDTSB70 length 1750mm- 3D STEP FILE -

4015.SDTSB70 length 1750mm

SDTSB70 length 1800mm- 3D STEP FILE -

4015.SDTSB70 length 1800mm

SDTSB70 length 1850mm- 3D STEP FILE -

4015.SDTSB70 length 1850mm

SDTSB70 length 1900mm- 3D STEP FILE -

4015.SDTSB70 length 1900mm

SDTSB70 length 1950mm- 3D STEP FILE -

4015.SDTSB70 length 1950mm

SDTSB70 length 2000mm- 3D STEP FILE -

4015.SDTSB70 length 2000mm

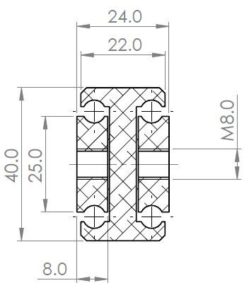

4015.ADTS040 – ADTS-40

4015.ADTS040 – ADTS-40