Sliding Systems has entered into a new distribution agreement with Regout Balance...

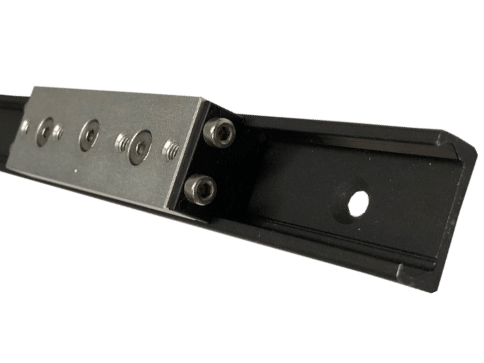

4080.TCA43 - Compact Slider - Alloy Body & Wiper

Saibo compact linear rails and sliders are designed for industrial applications requiring speed and precision. The compact design of the fixed rail is processed by grinding and induction hardening the raceways. This provides for high durability, precision and speed of operation.

All Saibo steel ball-races are induction hardened to 58+4 HRC similar to that of the running bearings, allowing for very low displacement forces, yet increased longitudinal acceleration. In addition to the induction hardened raceways, the beams have an enhanced black zinc 20µm corrosion protection which is both RoHS and REACH compliant. The manufacturing process is controlled by ISO9001/2015.

The mobile sliders (also known as carriers) have various mounting options, with 3, 4 or 5 bearing configurations to maximise performance. The slider body is manufactured from high grade aluminium alloy with anodised surface treatment. The precision bearings are sealed, with centrally mounted eccentric tolerance adjustment. This produces high loading, low noise, excellent rigidity and stable performance, even at the highest speeds.

The durability and excellent wear resistance of Saibo linear rails makes them ideal for applications such as train doors, automated machine guards and robotic precision pick & place. We presently have 28 and 43mm profiles, with 35mm to follow in 2020. Saibo telescopic slides & linear rails are designed as an economical drop-in replacement for current European manufactured product without compromising quality or performance.

- Ground raceways and induction hardened to 58+4 HRC

- Black Zinc 20µm Corrosion Protection

- Depth of hardening: Min 0.8mm

- Max operating speed: TV28 -5m/s TV43 -7m/s

- Max acceleration: 15m/s

- Max operational temp: 120 deg C

- Rails can be joined at achieve longer travel

- Wiper with lubrication pad standard on carriers

- Pre-load adjustment via central eccentric roller

- We recommend external stops are used during operation

Available ex-stock, usually on a same day despatch, the rails are supplied without end stops as standard. Upon customer request, we can manufacture these to drawing.

Data Sheet & main product information -

4080.TCA43 - 3D STEP FILE -

4080.TCA43 STEP File

4080.TCA43.3.A - Carrier - 3D STEP FILE -

4080.TCA43.3.A – Carrier

4080.TCA43.5.A - Carrier - 3D STEP FILE -

4080.TCA43.5.A - Carrier

4080.TCA43.5.B - Carrier - 3D STEP FILE -

4080.TCA43.5.B - Carrier

4080.TCA43 - 3D DWG FILE -

4080.TCA43 DWG File

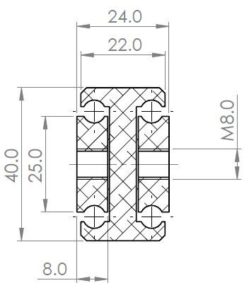

4015.ADTS040 – ADTS-40

4015.ADTS040 – ADTS-40