Sliding Systems has entered into a new distribution agreement with Regout Balance...

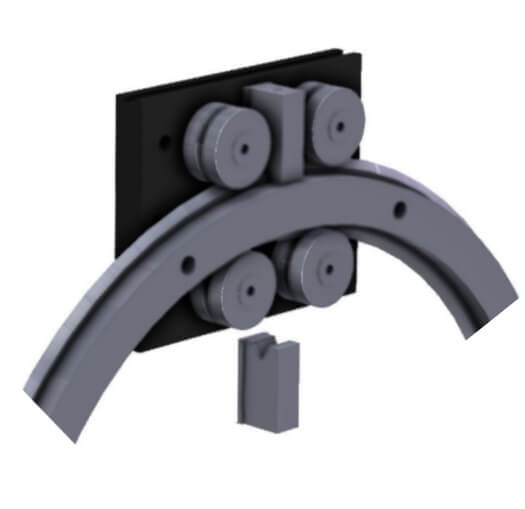

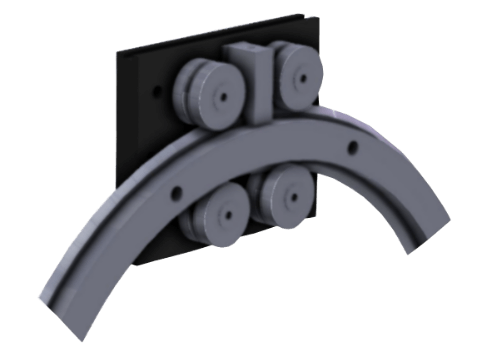

4080.CR & SRC - Ring & Carriage

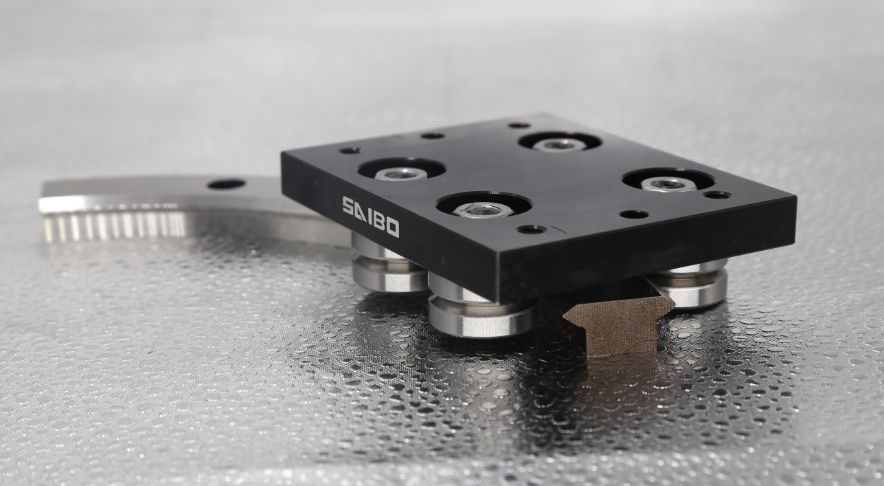

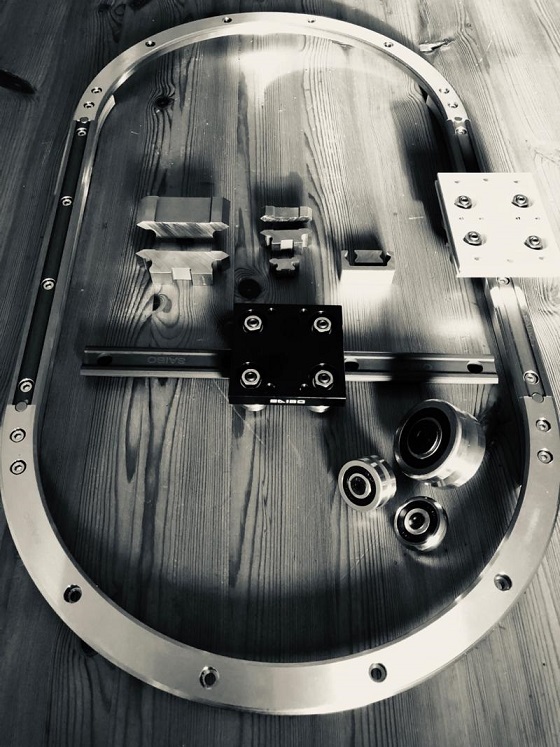

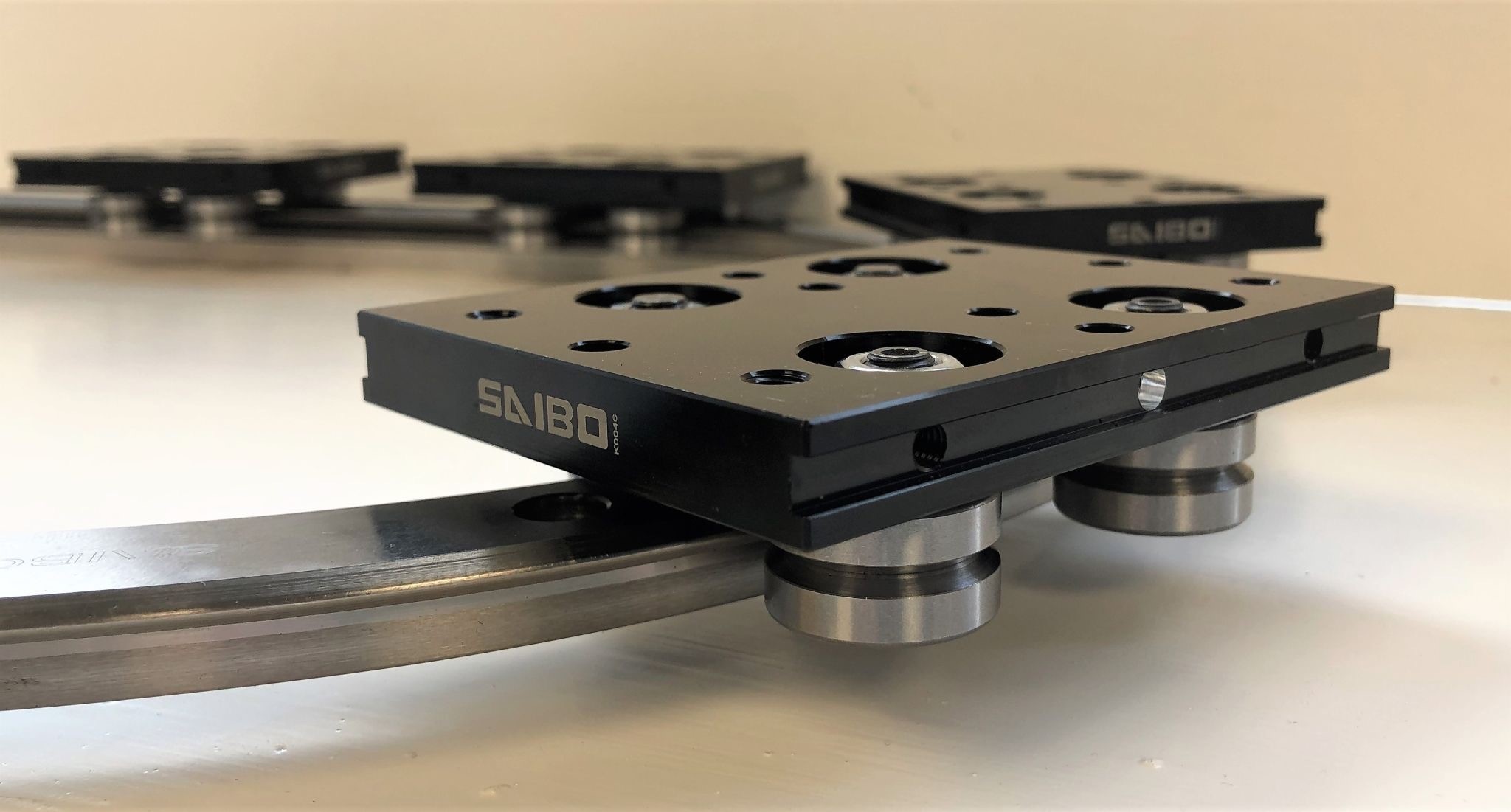

The Ring and Track system includes a V Edge Ring Rail, Carriage Plate, Concentric Bearings, Eccentric Bearings and Lubricators. These components are designed to be interchangeable with all international standard suppliers.

V Edge Ring Rail: Manufactured from high quality bearing steel. Deep hardened on the rails running surface for increased wear resistance. All surfaces including mount surfaces are ground for precision.

The 70° Double V running surfaces are ground together to ensure parallelism. Wide range of standard sizes available to suit most applications. All ring rails can be cut into segments, to suite customers design.

Additionally, Double Edge ring segments can be combined with linear Double Edge Rails to create Track Systems

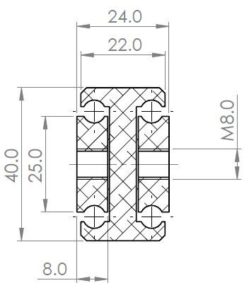

Concentric, Eccentric & Floating Bearings: Manufactured from high quality bearing steel. Whole body hardened for high wear resistance. Can be supplied as either Twin Double Row or Floating Bearings.

All bearings are supplied as standard with short fixing bolts, longer fixing bolts available on request.

Lubricated Wiper: The Lubricated felt wiper contacts the rails working surface to increase load capacity and life of the system. The felt wiper is pressed lightly by a small spring on to the rails working surface to ensure minimal friction. Lubricant is re-filled through a fill hole on back of the unit.

Data Sheet & main product information -

4080.CR25 255 R90 - 3D STEP FILE - ![]()

4080.CR25.255.R90

4080.CR25 255 R180 - 3D STEP FILE - ![]()

4080.CR25.255.R180

4080.CR25 255 R270 - 3D STEP FILE - ![]()

4080.CR25.255.R270

4080.CR25 255 R360 - 3D STEP FILE - ![]()

4080.CR25.255.R360

4080.CR25 351 R90 - 3D STEP FILE - ![]()

4080.CR25.351.R90

4080.CR25 351 R180 - 3D STEP FILE - ![]()

4080.CR25.351.R180

4080.CR25 351 R270 - 3D STEP FILE - ![]()

4080.CR25.351.R270

4080.CR25 351 R360 - 3D STEP FILE - ![]()

4080.CR25.351.R360

4080.SRC25.255 - 3D STEP FILE - ![]()

4080.SRC25.255.FCC - Carrier

4080.SRC25.351 - 3D STEP FILE - ![]()

4080.SRC25.351.FCC - Carrier

4080.CR44 468 R90 - 3D STEP FILE - ![]()

4080.CR44.468.R90

4080.CR44 468 R180 - 3D STEP FILE - ![]()

4080.CR44.468.R180

4080.CR44 468 R270 - 3D STEP FILE - ![]()

4080.CR44.468.R270

4080.CR44 468 R360 - 3D STEP FILE - ![]()

4080.CR44.468.R360

4080.CR44 612 R90 - 3D STEP FILE - ![]()

4080.CR44.612.R90

4080.CR44 612 R180 - 3D STEP FILE - ![]()

4080.CR44.612.R180

4080.CR44 612 R270 - 3D STEP FILE - ![]()

4080.CR44.612.R270

4080.CR44 612 R360 - 3D STEP FILE - ![]()

4080.CR44.612.R360

4080.SRC44.468 - 3D STEP FILE - ![]()

4080.SRC44.468.FCC - Carrier

4080.SRC44.612 - 3D STEP FILE - ![]()

4080.SRC44.612.FCC - Carrier

4015.ADTS040 – ADTS-40

4015.ADTS040 – ADTS-40