Sliding Systems has entered into a new distribution agreement with Regout Balance...

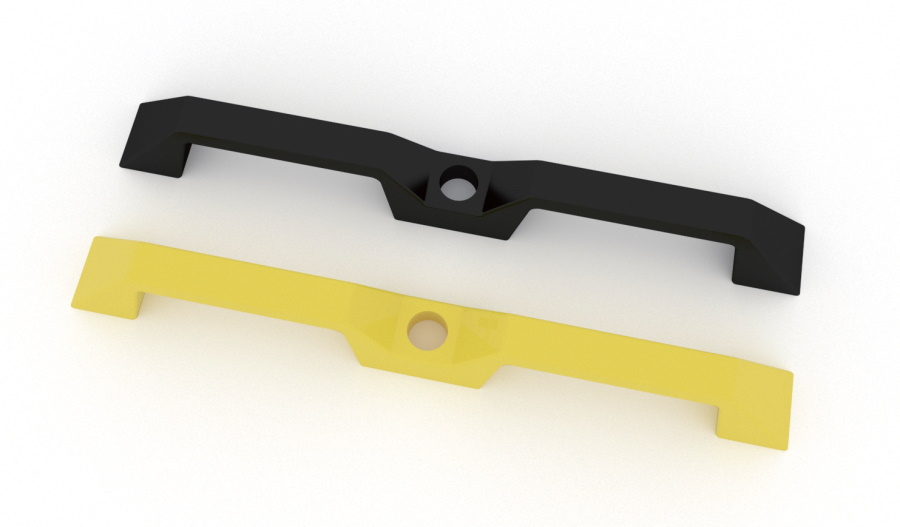

4073.BIHAND Handle Lock In & Out - Black / Yellow

Sliding Systems' Non-Corrosive, Heavy Duty Front Locking Handle is extensively used on fire truck and special vehicle drawers (straight slide out and slide and tilt). The double D handle and push button locking mechanism is located at the centre of the drawer front in order to ensure the operator's gloved hands are kept well away from pinch risks. Rated to 500kg, this is an efficient locking system.

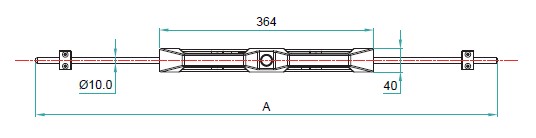

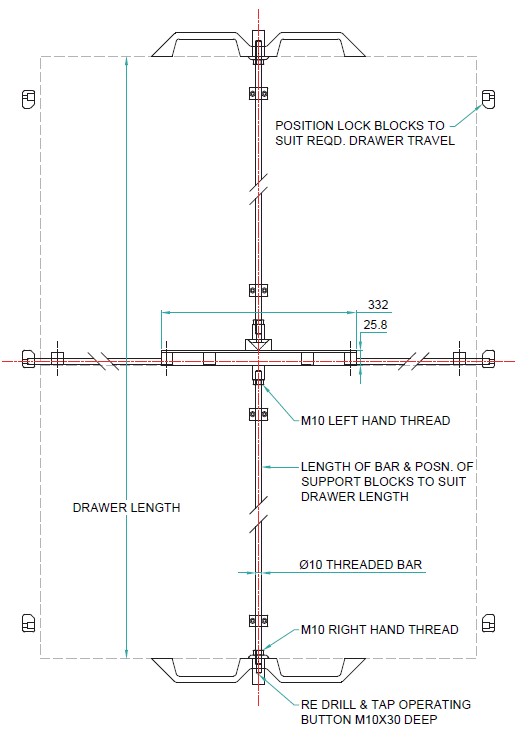

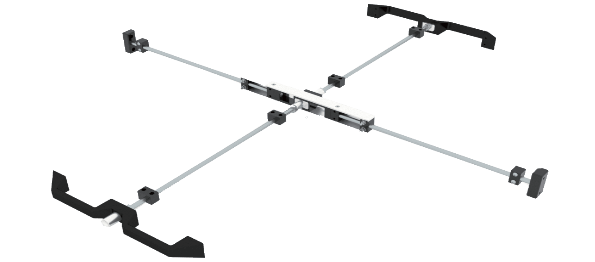

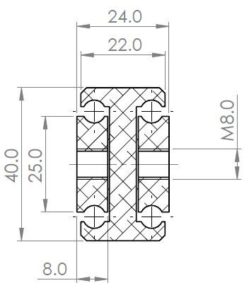

The Bi-Directional version of this locking handle allows for the locking mechanism and bars, to be fitted to centre of the drawer. Extra components are added, including a 2x 1000mm M10 threaded bar with BZP plating, extra threaded plungers, lock, and mounting blocks. All the kit needed to modify to a fully functioning Bi-Directional locking system.

The strong aluminium handle enables the operator to exert full control over the movement of what is likely to be a heavy drawer, both when opening and closing, and the locking mechanism can be installed, so as to provide a slam-shut lock-in functionality, as well as a lock-in and lock-out function. The locking mechanism retracts the spring-loaded locking bolts, which slot into the slam-shut lock blocks.

The handle is manufactured from cast aluminium with a specialist 7200 paint treatment designed for aerospace. The rods are supplied drilled and chamfered in 304 stainless steel. The plunger release is milled aluminium for weight reduction and strength. The housing is strong aluminium channel (not plastic!) and the internal components are moulded from strong GRP. The handle is supplied as a complete assembly, not in kit form. We own all the tooling for our handles.

The unit is generally supplied without an aluminium drawer front, and at standard widths of 540, 1040, 1540 and 2040mm. The user would then cut the locking bolts to their own desired width, although the system can be supplied with the locking bolts pre-cut to the user's specified length. HANDLE NOW AVAILABLE IN YELLOW FROM STOCK.

The drawer front is not supplied. The Heavy Duty Front Locks are available ex stock. Volume OEM prices available on request.

The Bi-Hand can be purchased online for global delivery by following this link

Code | Closed Length (mm) | Extension (mm) | Max Load Capacity (kg) |

|---|---|---|---|

| 4073.BIHAND.105 – BLACK | 540mm | 540mm | 500kg |

| 4073.BIHAND.109 – YELLOW | 540mm | 540mm | 500kg |

| 4073.BIHAND.106 – BLACK | 1040mm | 1040mm | 500kg |

| 4073.BIHAND.110 – YELLOW | 1040mm | 1040mm | 500kg |

| 4073.BIHAND.107 – BLACK | 1540mm | 1540mm | 500kg |

| 4073.BIHAND.111 – YELLOW | 1540mm | 1540mm | 500kg |

| 4073.BIHAND.108 – BLACK | 2040mm | 2040mm | 500kg |

| 4073.BIHAND.112 – YELLOW | 2040mm | 2040mm | 500kg |

Bi-Hand Datasheet

Locking Handle Installation Guide

4073.BIHAND 540mm - Black

4073.BIHAND - 540mm Black

4073.BIHAND 1040mm - Black

4073.BIHAND - 1040mm Black

4073.BIHAND 1540mm - Black

4073.BIHAND - 1540mm Black

4073.BIHAND 2040mm - Black

4073.BIHAND - 2040mm Black

4073.BIHAND 540mm - Yellow

4073.BIHAND - 540mm Yellow

4073.BIHAND 1040mm - Yellow

4073.BIHAND - 1040mm Yellow

4073.BIHAND 1540mm - Yellow

4073.BIHAND - 1540mm Yellow

4073.BIHAND 2040mm - Yellow

4073.BIHAND - 2040mm Yellow

4015.ADTS040 – ADTS-40

4015.ADTS040 – ADTS-40