Sliding Systems has entered into a new distribution agreement with Regout Balance...

4012.LBSO Chassis Trak LBS-O-LO – Lock Out

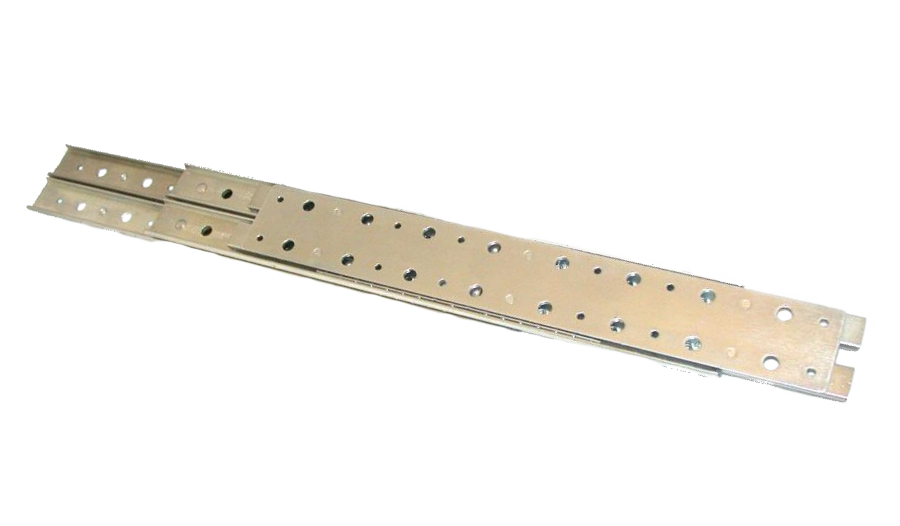

Chassis Trak LBS-O-LO Full Extension Slide With Lock Out Facility As Standard

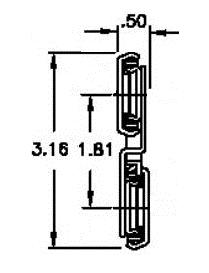

1. LBS-O consists of one right hand and one left hand slide pair. Optional lock-out feature is available.

2. All slides are supplied with special (.094” max. head height) #8-32x3/8 Phillips pan head screws and self-locking nuts for mounting one set of slides. Use only these special screws when mounting through slide member to prevent internal damage to ball retainer. If mounting to cabinet rails, see cabinet mounting section for ball bearing slides.

3. LBS-O does not disconnect.

4. Slide members are made from 14 gauge (.074) work hardened cold rolled steel.

5. Finish: clear zinc commercial plating.

6. Holes other than those shown may be in part at manufacture’s option.

7. Load capacity is based on one set of slides at full extension with load (center of gravity) centered between the slides and at midpoint of the slide (chassis section). Load capacities have a 100% (static load) safety factor at full extension. The slides will support more than the stated capacities but are not designed to be operated at capacities greater than those stated.

8. Grease applied to ball bearing slides has a temperature range of –45ºF to +350ºF.

9. Odd length slides available, contact factory for more information.

10. Other non-standard options which are available include: special marking, special extensions, special finishes, lock-in and complete design changes per customer request. Contact factory as these options will require a special reference number to assure receipt of specified options.

All General Devices slides are manufactured to order, so please allow 5-6 weeks, unless subscribed to our stockholding programme. 3D .stp files available on request.

Our Chassis Trak slides are priced and sold per pair and not singularly. OEM discounts for scheduled orders please enquire.

Code |

Closed Length (in) |

Extension (in) |

Max Load Capacity (kg) |

|---|---|---|---|

| 4012.LBSO.010 | 10in | 11in | 82kg |

| 4012.LBSO.012 | 12in | 13in | 79kg |

| 4012.LBSO.014 | 14in | 15in | 77kg |

| 4012.LBSO.016 | 16in | 17in | 72kg |

| 4012.LBSO.018 | 18in | 19in | 68kg |

| 4012.LBSO.020 | 20in | 21in | 66kg |

| 4012.LBSO.022 | 22in | 23in | 59kg |

| 4012.LBSO.024 | 24in | 25in | 52kg |

| 4012.LBSO.026 | 26in | 27in | 48kg |

| 4012.LBSO.028 | 28in | 29in | 41kg |

| 4012.LBSO.030 | 30in | 31in | 34kg |

Data Sheet & main product information -

Installation Sheet -

4012.LBSO - 254mm (10") - 3D STEP FILE - ![]() 4012.LBSO length 254mm (10") - LEFT

4012.LBSO length 254mm (10") - LEFT

4012.LBSO - 254mm (10") - 3D STEP FILE - ![]() 4012.LBSO length 254mm (10") - RIGHT

4012.LBSO length 254mm (10") - RIGHT

4012.LBSO - 304mm (12") - 3D STEP FILE - ![]() 4012.LBSO length 304mm (12") - LEFT

4012.LBSO length 304mm (12") - LEFT

4012.LBSO - 304mm (12") - 3D STEP FILE - ![]() 4012.LBSO length 304mm (12") - RIGHT

4012.LBSO length 304mm (12") - RIGHT

4012.LBSO - 356mm (14") - 3D STEP FILE - ![]() 4012.LBSO length 356mm (14") - LEFT

4012.LBSO length 356mm (14") - LEFT

4012.LBSO - 356mm (14") - 3D STEP FILE - ![]() 4012.LBSO length 356mm (14") - RIGHT

4012.LBSO length 356mm (14") - RIGHT

4012.LBSO - 406mm (16") - 3D STEP FILE - ![]() 4012.LBSO length 406mm (16") - LEFT

4012.LBSO length 406mm (16") - LEFT

4012.LBSO - 406mm (16") - 3D STEP FILE - ![]() 4012.LBSO length 406mm (16") - RIGHT

4012.LBSO length 406mm (16") - RIGHT

4012.LBSO - 457mm (18") - 3D STEP FILE - ![]() 4012.LBSO length 457mm (18") - LEFT

4012.LBSO length 457mm (18") - LEFT

4012.LBSO - 457mm (18") - 3D STEP FILE - ![]() 4012.LBSO length 457mm (18") - RIGHT

4012.LBSO length 457mm (18") - RIGHT

4012.LBSO - 508mm (20") - 3D STEP FILE - ![]() 4012.LBSO length 508mm (20") - LEFT

4012.LBSO length 508mm (20") - LEFT

4012.LBSO - 508mm (20") - 3D STEP FILE - ![]() 4012.LBSO length 508mm (20") - RIGHT

4012.LBSO length 508mm (20") - RIGHT

4012.LBSO - 559mm (22") - 3D STEP FILE - ![]() 4012.LBSO length 559mm (22") - LEFT

4012.LBSO length 559mm (22") - LEFT

4012.LBSO - 559mm (22") - 3D STEP FILE - ![]() 4012.LBSO length 559mm (22") - RIGHT

4012.LBSO length 559mm (22") - RIGHT

4012.LBSO - 610mm (24") - 3D STEP FILE - ![]() 4012.LBSO length 610mm (24") - LEFT

4012.LBSO length 610mm (24") - LEFT

4012.LBSO - 610mm (24") - 3D STEP FILE - ![]() 4012.LBSO length 610mm (24") - RIGHT

4012.LBSO length 610mm (24") - RIGHT

4012.LBSO - 660mm (26") - 3D STEP FILE - ![]() 4012.LBSO length 660mm (26") - LEFT

4012.LBSO length 660mm (26") - LEFT

4012.LBSO - 660mm (26") - 3D STEP FILE - ![]() 4012.LBSO length 660mm (26") - RIGHT

4012.LBSO length 660mm (26") - RIGHT

4012.LBSO - 711mm (28") - 3D STEP FILE - ![]() 4012.LBSO length 711mm (28") - LEFT

4012.LBSO length 711mm (28") - LEFT

4012.LBSO - 711mm (28") - 3D STEP FILE - ![]() 4012.LBSO length 711mm (28") - RIGHT

4012.LBSO length 711mm (28") - RIGHT

4012.LBSO - 762mm (30") - 3D STEP FILE - ![]() 4012.LBSO length 762mm (30") - LEFT

4012.LBSO length 762mm (30") - LEFT

4012.LBSO - 762mm (30") - 3D STEP FILE - ![]() 4012.LBSO length 762mm (30") - RIGHT

4012.LBSO length 762mm (30") - RIGHT

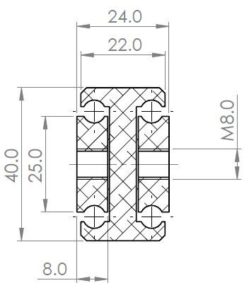

4015.ADTS040 – ADTS-40

4015.ADTS040 – ADTS-40