Sliding Systems were approached by a global market leader in emergency vehicle builds with very exacting requirements, which they were unable to source locally. We have the widest range of extreme duty slides available anywhere, so our Technical Director Jon Lye saw this as a personal challenge –

*

”We were tasked with providing ten drawer sets per vehicle using four different types of telescopic slide. This in itself wasn’t the challenge, as one 2300mm mid mounted drawer had to operate bi-directionally with travel of 1600mm front and rear whilst supporting a massive 680kg. We selected a modified DTSB90 length 2300mm and under-travel of 1600mm with stainless steel bearings. These are front line trucks and the end user will expect a long service life”

*

The other three drawer sets were challenging in their own ways, but each was dealt with by using standard profiles with elements of modification –

*

”Six of the drawers required an over travel of 120%. This is something we pioneered at Sliding Systems and have considerable experience in extreme extensions, even up to 200%. The specification was to support 484kg with a travel of 1250mm from a tight stowed space of 1050mm. The requirement was for all the slides to have stainless bearings, so this was a no cost option. The new 60mm profile DTS60 was the natural choice”

*

Jon continues – ”We then had a specialist drawer requiring the usual 120% over travel from 700mm stowed space and supporting 680kg. This allowed the back of the drawer to extend out 840mm and utilse the full space, even offering four personnel the room to lift any bulky objects out without being obstructed by the truck body”

*

”The smallest drawer had its’ own demands – this time an obstruction required an under extension. That is a travel of exactly 433mm from a 450mm closed position. The loading was a mere 300kg”

*

Then there was the matter of manufacturing these slides in under 5 weeks and shipping out for fitting, whilst already starting the long term production schedule.

*

Jon concludes: ”We offer service and a great product. Most of this design process was carried out over the Christmas holidays as the customer had a very tight schedule to work within. We relish a challenge and this extended to me finding a quiet corner in the local pub on new Years Eve at 10pm and supplying the technical information for them to make an informed decision. This is how global businesses work these days, it’s full on and responsive”

*

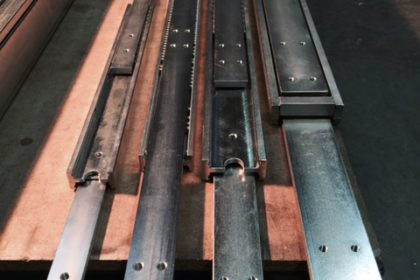

We can show images of the slides, however as with most security projects, the trucks are off limits for now.

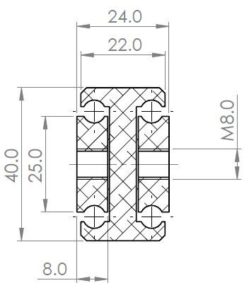

4015.ADTS040 – ADTS-40

4015.ADTS040 – ADTS-40