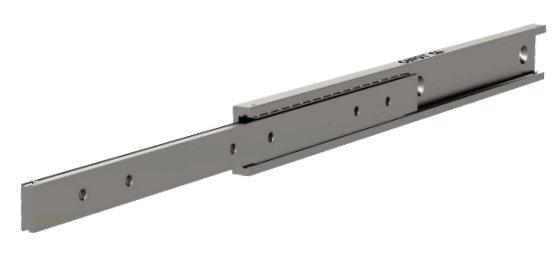

The OWST-50 Küçük bir alan zarfından yükü maksimuma çıkarmak için tasarlanmış, kısmen öne ve arkaya uzanacak şekilde donatılmış sağlam bir kızaktır. Özellikle uygun itfaiye aracı çekmeceli ve elle çalıştırılan makine korumasıÖnden ve arkadan erişimin gerekli olduğu yerlerde. Burulma dayanımının çok önemli olduğu geniş bir uygulama yelpazesine sahiptir. OWST slaytlar, tamamen uzatıldığında istifleme konumundan çift olarak çalışacak şekilde monte edilebilir. Bu, iç ışının merkezi konumdan geçip arkaya doğru hareket etmesiyle %100 tam hareket sağlar. Veri sayfası, bu ikili uzantının slaydın kapalı uzunluğuna eşit olduğunu belirtir. Ancak tipik kullanım, kapalıyken merkezi konumdan öne ve arkaya %50 harekettir.

OWST-50 aşırı yük/görev %50 uzatmalı bir kızaktır (70-485 kg/çift). 550 mm'de 1 çift, her yönde 275 mm hareket mesafesine sahiptir ve 460 kg yük kapasitesi vardır. Soğuk çekilmiş çelik kesitlerden ve hassas öğütülmüş bilya raylarından yapılmış olan OWST-50 teleskopik kızak, kapalı konumda statik bir yükü desteklerken şok ve titreşime karşı mükemmel bir dirence sahiptir. Buna göre bu çekmece rayları araçların içine monte edilmeye çok uygundur. Bu teleskopik kızak, yüksek yük kapasitesi için kompakt bir tasarım sunar. Kızak ayrıca uzatılmış konumdayken uygulanan yüklere karşı iyi bir dirence sahiptir ve bu da onu dinamik uygulamalar ve manuel olarak çalıştırılan sistemler için mükemmel bir seçim haline getirir.

The OWST-50 çekmece sürgüsü aynı zamanda yan eksene (düz) de takılabilir. Ancak yük kapasitesi belirtilen yüklemenin %60-80'i oranında azalacaktır. Yükü bir miktar azaltacak %70 uzatma ile tedarik edilebilir. Bu ücretsiz seçenek için lütfen satış mühendislerimize danışın. Üretime geçmeden önce fabrika uyarlaması ve müşteri yerinde testleri yapılmadan, doğru robotik alma ve yerleştirme veya yüksek hızlı mekiklerde standart OWST slaytlarını önermiyoruz. Kaydıraklar <0.3 m/s'lik çalışma hızlarıyla sınırlıdır

Üretim süreci ISO9001-2015 akreditasyonuna sahiptir. Çelik teleskopik kızaklarımız EN 45'ye uygun soğuk çekilmiş çelik C10277E+C'den üretilmektedir. Lazer kesim bilya kafesleri çinko kaplı sacdan imal edilmiş olup, bilya yatakları DIN 85'e uygun C100 G5401 karbon çeliğidir. Standart Profesyonel Seri çelik slaytlar, kırmızı pas görünene kadar 1,000 saatten fazla korozyon korumasına dayanacak şekilde RoHS ve REACH sertifikalıdır. Bu, kendi son teknoloji elektrolitik alkali çinko işleme tesisimize yaptığımız yatırımdan kaynaklanmaktadır. DIN EN ISO 45 nötr tuz püskürtme testine uygun, 10-12 mikron katman derinliğine sahip C9227 E+C çekirdek çeliği. 120 saat içerisinde beyaz pas görünümü görülmez. 1,032 saat içinde kırmızı pas görülmedi.

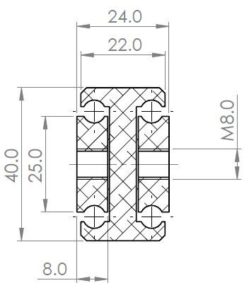

Tek bir slaytın ağırlığı metre başına 5.53 kg'dır.

OWST-50, bu bağlantıyı takip ederek küresel teslimat için çevrimiçi olarak satın alınabilir.

Fiyatlar tek slayt başınadır. Yükler uzatılmış çift başına verilmiştir. Çift başına iki slayt vardır. OWST-50 sipariş üzerine üretilmektedir. Lütfen teslimat için 5-6 hafta bekleyin veya planlı siparişlere karşı derhal iptal edilmek üzere stoklanabilir.

4015.ADTS040 – ADTS-40

4015.ADTS040 – ADTS-40